From wind energy to electricity generation

PDF

The challenge of emitting less and less CO2 in order to limit global warming calls for the design of a low-carbon electricity mix in which hydraulic, nuclear, hydrogen, solar, wind and other renewable energies are combined. Wind installed power has been growing rapidly since the early 1980s. This development concerns many countries and, for the last twenty years, offshore sites. The stakes are such that not a day goes by without discussions in the media on the various conceivable electricity mix. In this context, what can be the contribution of the wind field and what are its characteristics? How do modern industrial wind turbines work? Is wind electricity competitive? What pressure does it generate on the territories, what is the consumption of raw material for these equipments and what are the constraints for the development of wind farms?

1. The wind resource: an accessible, inexhaustible energy resource that can be exploited on land and offshore

The low altitude wind resource is the result of the movement of air masses around the earth. It is produced by solar radiation, the Earth’s rotation and the relief, which can accelerate or slow down the wind speed. As the air particles move, they acquire kinetic energy and exert pressure on any surfaces or obstacles they encounter. They are able to supply a driving torque and running aerodynamic machines of varying degrees of sophistication. Electricity is produced when a generator is coupled to the turbine’s drive shaft. In this case we speak of wind generators [1].

Until the beginning of the 1970s, the conversion of wind energy was mainly aimed at the production of mechanical energy on isolated sites equipped with “windmills” to activate flour mills, textile workshops, water pumps, etc.

For the last fifty years, wind energy has been used for the “industrial” generation[2] of electricity thanks to the progressive implementation on all continents of wind

gathered together in the vast majority of cases to form wind farms. These industrial installations benefit from an incremental technological progress related to the experience feedback consolidated from hundreds of thousands of wind turbines installed around the world.

The wind turbines [3] are in the vast majority of cases of the Danish technology – three blades in front of the wind [4] . They are increasingly large; they have a higher nominal power (multi-MW); they are more efficient and safe.

The main stages that characterize the diffusion of this type of electricity generation equipment on land are: in North America, the “Californian Wind Rush” in the 1970s and 1980s, then the development in Europe (Denmark, Netherlands, Germany, Sweden, Spain, United Kingdom). The start of the exploitation of the wind farms will follow in France with a delay of about ten years, then from the years 2000, it will concern Southeast Asia (mainly China and India).

The development of offshore wind farms [5] began in the early 2000s in shallow water (a few metres) near the coasts of pioneering countries (Denmark, the Netherlands, the United Kingdom, Germany) and is progressively extending to deeper sites (a few tens of metres) further from the coasts (a few kilometres to several tens of kilometres, or even a hundred kilometres from the coasts in the future).

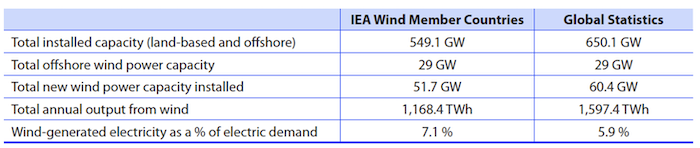

Table 1: Key figures for global wind power generation in 2019 [Source: IEA (2019), IEA Wind TCP Annual Report 2019. all rights reserved]

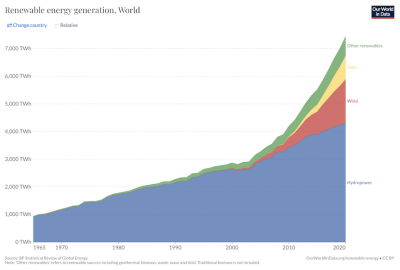

In 2019, wind power generation in the world stands at more than 1,597 TWh virtually carbon-free [6], corresponding to an installed capacity at the end of the year of 650 GW (onshore + offshore), including 29 GW for offshore wind.

1.1. Characterization of the wind resource

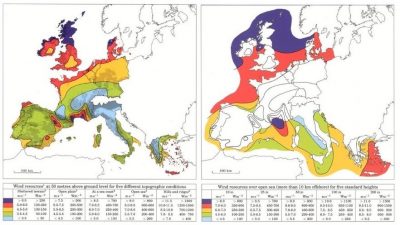

Nowadays, the wind resource can be evaluated with a good accuracy at the regional or national level (large scale of a few tens to several hundreds of kilometres) or locally (tight scale of a few hundred metres to a few kilometres).

To do this, analysts have access to measurements taken by satellites and by local weather stations which have accumulated reliable wind measurement records in most countries. They also have at their disposal numerical models to rebuild the wind flow in three dimensions and, above all, the high quality data bank of wind measurements from reference stations and masts [7] in wind farms and from the recorders on board all modern wind turbines in operation.

A large number of public [8] and private institutions contribute to the assessment of onshore and offshore wind resource. The constructive cooperation between experts also facilitates the exchange of data between the different actors.

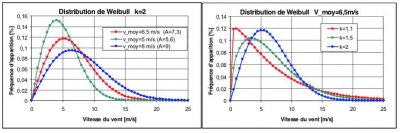

In practice, to estimate the local wind resource, it is common to approximate the wind speed distributions from experimental and discrete recorded data (e.g. with a speed step of 1 m/s) by a Weibull distribution whose two parameters A and k have to be defined, depending on the geography of the site:

f(v) = k/A.(v/A)k-1 exp[-(v/A)k

- A is a scaling parameter close to the average wind speed,

- k is a shape parameter representative of the more or less pronounced turbulence of the site. The lower k is, the more turbulent the site is. For land sites in Europe, a value close to 2 can be considered as a first approach (except for complex sites).

The wind is variable in strength and direction. This results in a statistical hazard that affects the wind resource and consequently the electricity generation.

1.2. Wind Turbines

1.2.1. Vertical Axis Wind Turbines

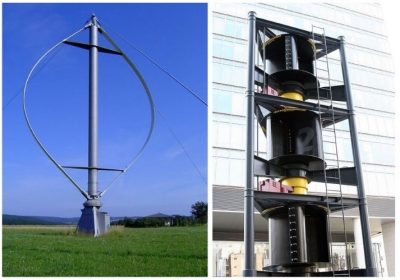

At the beginning of the 20th century, when windmills were appearing in increasing numbers in different parts of the world, especially in Scandinavia, a French engineer Georges Darrieus [10] and a Finnish architect and inventor Sigurd Savonius [11] filed several patents for the transformation of mechanical wind energy using vertical axis wind turbines [12]. These patents were intended to be a technological breakthrough.

1.2.2. Horizontal axis wind turbines

1.3. Conversion of wind energy into electricity generation

Electricity generation is a preferential way [14]. If there were no other constraints, in particular with regard to the environment and the inhabitants, modern wind turbines spread over the different continents would be able to produce volumes of electricity under satisfactory technical and economic conditions [15] that would be greater than the world’s electricity generation [16], all technological sectors combined.

On the ground, the major obstacle to the massive development of wind power is the impact on the environment and the conflicts of use [17] that some opponents or organised pressure groups consider here and there as harmful to the community.

The scientific community and wind industry now have fifty years of international experience. They have made “reasonable” technical and economic choices that are now imposed worldwide.

These choices structure the development and operation of wind energy: (i) almost all wind power installations are designed for industrial electricity generation; (ii) wind turbines are gathered together in electricity power plants – often called wind farms – of significant power (a few MW to several tens of MW or even several hundred MW installed, especially in the case of offshore sites) which are connected to the public electricity distribution or transmission network and deliver to the latter all the electrical energy generated, minus losses in the wind farm’s internal network ; iii) electricity power is provided by “multi-MW” wind turbines [18], which are sophisticated, mass-produced aerodynamic machines that convert wind energy in an open environment, with a horizontal axis and very generally three blades in front of the wind.

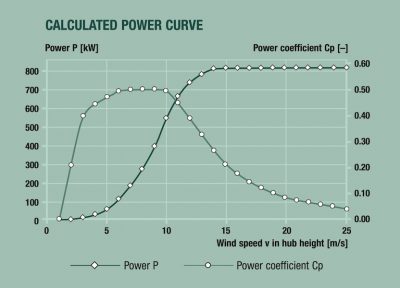

The aerodynamic power available at the drive shaft is expressed with the formula:

Pmechanical = Cp.1/2.ρ.S.V13

In which Cp denotes the power regulation coefficient, or aerodynamic efficiency of the machine (Cp< 1), ρ being the air density [19], S the area swept by the rotor, and V1 the wind speed upstream of the rotor.

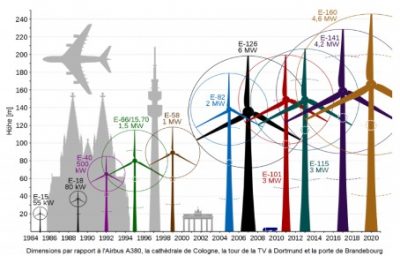

1.4. Wind turbine technology: evolution and progress

Over the past 40 years, wind turbine technology has been evolving steadily, with incremental progress [21]. The performance of the machines (energy efficiency, technical-economic performance, reliability, safety, etc.) has been improving over time. They thus adapt and meet the specifications of the rapidly growing international demand.

The main developments concern the following links in the energy conversion process:

- Blades and aerodynamic regulation,

- The transmission of the engine torque,

- The electricity generator,

- The speed and electrical power regulation.

The table below presents a summary of the most emblematic technological advances that have been made in Danish-type wind turbines, with three blades in front of the wind, since the 1980s.

Table 2: Summary of technological advances in wind turbines since 1980 [Source: Compilation by the author of technical characteristics of wind turbines marketed by different manufacturers, 2021, Encyclopedia of the Environment, www.encyclopedie-environnement.org]

| Technological advances | Blades | Transmission of the Engine torque | Electricity Generator | Speed and electrical power control |

| 1st Generation of wind turbines | Fixed blades with a safety pit [22] at the end of the blade.

Aerodynamic “stall [23]” control. |

Shaft with 3-stage gearbox. | Asynchronous generator with single magnetic field | Almost fixed blade speed (slip limited by the asynchronous generator).

No effective electrical power regulation. |

| 2nd Generation | Variable blade orientation. Pitch control [24] aerodynamic control + spoiler [25] at the end of the blade. | Shaft with 3-stage gearbox. | Asynchronous generator with double magnetic field. | Variable blade rotation speed. Electronic control of electricity power. |

| 3rd Generation | Variable blade orientation. Regulation

aerodynamic “Pitch control + spoiler at blade tip. |

Direct drive (without gearbox) or single stage gearbox. | Synchronous alternator (induction by stator current or by permanent magnets). | Electronic control of blade speed, active and reactive electricity power. |

No effective electrical power regulation.

Electronic control of electricity power.

aerodynamic

“Pitch control + spoiler at blade tip.

2. Wind power generation: neutralized surfaces and embedded raw materials

2.1. Neutralised surfaces [27] in the areas

In the case of a wind farm with several turbines, wake effects are more or less important depending on the distance between the turbines and the wind direction. To reduce these effects, which degrade the weighted average power conversion coefficient Cp of the wind farm, a minimum distance between turbines is recommended, of the order of 5 to 10 times their diameter, depending on the relief of the site and the wind distribution (speed and direction). The technical-economic compromise between the number of wind turbines installed, the annual electricity generation, the land area dedicated to this purpose, the impact on the environment, on the community and on the inhabitants is then sought [28].

The average rated power of wind turbines installed in 2019 worldwide is 2.75 MW [29] compared to 1.5 MW ten years earlier. To achieve this power rating (2.75 MW), the rotor diameter of wind turbines currently on the market is between 110 and 125 m depending on the model [30]. Thanks to the productivity of modern machines, the installed electrical power density can exceed 20 MW/km2 of land neutralised by wind turbines today.

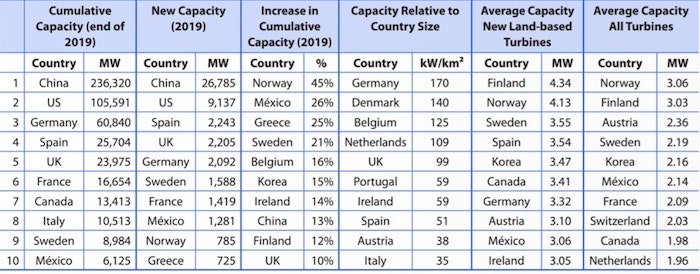

The report of the International Energy Agency (2019) provides the ranking of the “Top Ten” countries according to, among other things, the average power of wind turbines installed at the end of 2019 and the density of installed power related to the surface area of the countries, which characterizes the “pressure” of wind power generation on the territories.

Table 3: Ranking of “Top Ten” countries according to several criteria, including the density of installed wind power capacity per km2 of country area [Source: IEA (2019),[IEA Wind TCP Annual Report 2019. All rights reserved]

2.2. Materials and components embedded in wind turbines

The technology, dimensions and mass of wind turbines have evolved over the last decades in order to make the most of the kinetic energy of the wind and generate electricity in the most favourable technical and economic conditions, taking into account the low density of air (1.292 kg/m3).

The construction and installation of a wind turbine generator on site involves the assembly of the following main components: the foundation, which is almost always gravitational for onshore sites, the mast [32], the nacelle or “hub”, the rotor on which three blades are articulated according to the technology adopted today by almost all machines [33].

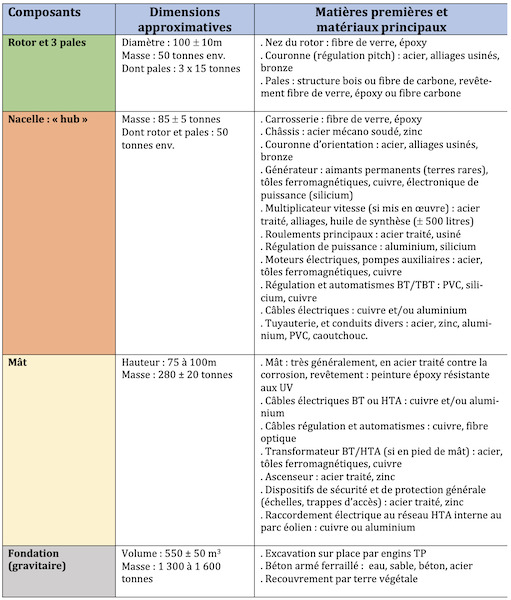

The following table shows the dimensions, weights and essential raw materials used in the manufacture and installation of a 2.5 MW wind turbine on land (nominal power close to the average installed in 2020 worldwide).

Table 4: Main components, dimensions and approximate masses. Brief inventory of materials used in the manufacture of a 2.5 MW wind turbine generator and for the gravity foundation [Source: Based on the comparative characteristics of several wind turbines (rated power: 2.5 MW), 2021, Encyclopedia of the Environment, www.encyclopedie-environnement.org]

2.3.3. The “grey” energy [35] required for the construction and dismantling of onshore wind farms

In addition to the manufacture of the wind turbines and their components in the workshop, and the exceptional transport of these elements to the site, the development of wind farms requires the realization of important public works for the infrastructures and roads:

- Roads: paved tracks or roads allowing access to the different wind turbines, to the energy delivery station, to the wind measurement mast(s), meteorological station, etc.

- The water network, the spreading fields,

- The wind farm’s internal electrical distribution network, generally medium voltage HTA (20 kV), the telecommunications network,

- The electricity delivery station for connection to the public distribution network (medium voltage HTA) or to the transport network (high voltage HTB), depending on the power of the wind farm.

At the end of the equipment’s lifetime and the operating period, i.e. after an operating period of 20 to 25 years in the vast majority of cases, the project owner has the duty [36] to restore the site. This phase – known as the deconstruction of the power plant – calls for major dismantling work, sorting of raw materials, cutting up of components, restoration, revegetation of the site, etc.

The “grey” energy absorbed by a wind farm is the result of complex analyses and the application of digital models. It differs according to whether the wind farms are onshore or offshore.

Concerning the production of wind electricity on land [37], studies converge towards a return time of the “grey” energy equivalent to 12 months of the wind farm’s producibility. Under these conditions, the carbon content [38] of the wind kWh is between 20 and 30 grams of CO2/kWh, which is lower than the weighted average emission rate (close to 80 grams of CO2 equivalent/kWh) for the French electricity production fleet [39] in 2020, which is one of the least carbon-intensive countries in the EU.

2.4. Value of wind power generation

Wind turbines in operation convert available wind energy close to the earth’s surface, which is renewable, carbon-free, into a quantity of electricity ranging from 1,700 to 2,200 MWh [40] per installed MW per year, depending on the land site and operating conditions.

The average discounted production cost of electricity (LCOE [41]) for wind power is competitive, ranging from 70 to 80 €/MWh [42] in France.

Moreover, this “green” energy is very low carbon [43]. It thus contributes to carbon emissions avoided in most electricity mixes, which generally have a higher “carbon” signature due to the operation of fossil fuel power plants.

3. Messages to remember

- The low altitude wind resource is considerable, well distributed on the continents and on the oceans. It can be evaluated by different complementary methods and is well documented today.

- The production of electricity by wind turbines with increasingly large dimensions and characteristics (multi-MW machines) grouped in industrial wind farms (critical size: several tens of MW on land, several hundred MW at sea) connected to the public electricity grid (medium or high voltage) is the industrial process that optimizes the conversion of wind energy into an efficient and renewable energy vector today. In 2019, wind power generation (onshore and offshore) accounted for 5.9% of global electricity demand.

- Wind power generation, whether onshore or offshore, neutralizes land; it remains a “grey” energy consuming industry during the manufacture of wind turbines and the development of wind farms; however, this remains limited to the equivalent of one year’s production. Relying on the efficiency of a proven and optimized technology over the last forty years, wind electricity is globally very low in carbon (20 to 30 gr of CO2/kWh).

- In addition to being a renewable energy, the production of wind electricity is a source of value: the production cost of the MWh on land is competitive (France: 70 to 80 €/MWh depending on the wind field), which makes it essential to contribute to an efficient and less and less carbon intensive electricity mix.

Notes and references

Cover image. Aerial view of Rodby Fjord wind farm in Denmark, 11 wind turbines (VESTAS 3.0 MW platform, rotor diameter: 117m) Rodby Fjord wind farm, commissioned 2016, Denmark [Source: VESTAS Wind Systems A/S, www.vestas.com, rights reserved]

[1] MULTON, B. et al, Electric Aerogenerators, Techniques de l’Ingénieur, https://www.techniques-ingenieur.fr

[2] The term “industrial” wind power generation refers to the electrical energy produced by wind farms consisting of one or usually several wind turbines with a unitary power of several MW – nowadays – which is fed into the public electricity grid. As opposed to isolated wind power generation for the supply of installations or buildings connected or not to the public electricity grid: agricultural installations, mountain huts, etc.

[3] BESLIN, G. and MULTON, B., 2016, Production éolienne : de son gisement éolien à ses aérogénérateurs, Encyclopédie de l’Énergie, www.encyclopedie-energie.org

[4] Some models of two-bladed wind turbines of lower power are marketed to equip isolated sites or sites where the wind resource is complex: turbulence, cyclonic phenomena.

[5] Offshore wind power installations are most often included in the category of marine renewable energy sources, with the development conditions specific to the marine environment taking precedence over the energy source.

[6] The carbon impact of wind power is very low. Since the energy conversion process is carbon-free, the carbon footprint to be accounted for is the “grey” energy, as discussed below, consumed in the manufacture of the wind turbines, transportation of the turbines, site development, construction of the foundations and, at the end of the operating life of the facility, decommissioning operations.

[7] Before the construction of a wind farm, one or more wind measuring masts (height: 10 to 50m or even more for some sites) are installed in situ in order to carry out the preliminary studies and the engineering of the wind farm. These measuring masts are generally kept during the operation of the production facility. They can then be used as a reference to calibrate the recorders installed in the wind turbines.

[8] Political and governmental bodies, international organisations such as the European Commission, the US Department of Energy (DOE), the World Bank, etc. contribute to the financing of onshore and offshore wind farm studies.

[9] Europe’s onshore and offshore wind energy potential. An assessment of environmental and economic constraints, 2009, European Commission, https://www.energy.eu/publications/a07.pdf

[10] Georges Darrieus (1888 – 1979): French engineer who held various positions at the Compagnie Electro Mécanique (CEM). He filed a patent in 1927 on the vertical axis wind turbine.

[11] Sigurd Savonius (1884 – 1931): Finnish architect and inventor. He designed the vertical axis wind turbine with a hemispherical rotor. The driving torque results from the aerodynamic flow (deflection) in the hemispherical cups.

[12] The operation of a Darrieus wind turbine is based on the lift effect of an airfoil or wing subjected to the force of a relative wind, which will cause the airfoil or wing to rotate around a vertical axis. The Savonius wind turbine consists of two or more buckets or semi-cylindrical airfoils, which are rotated around a vertical axis by the wind.

[13] The “Danish” type of wind turbine has become established on the market. It has a rotor at the top of the mast, usually with three blades. The rotor is mounted on a bearing and is oriented according to the wind direction so that the blades can turn into the wind.

At the time of the rush in the United States, the wind turbines installed in California were of the Danish type. Most western countries have developed prototypes of horizontal axis wind turbines (three-bladed or not). In France, an 800 kW three-bladed wind turbine was designed by Lucien Romani, Bureau d’Études Scientifiques et Techniques (BEST) in the 1950s.

[14] Course material: CRESSAULT, Y., Eoliennes, 2015 – 2016, Laboratoire Laplace, Université de Toulouse, https://btsfed.lyceevinciblanquefort.fr/lib/exe/fetch.php?media=2015:ads:cours-eoliennes_lessentiel.pdf

[15] We can say that wind electricity is competitive if the technical conditions of production are reliable and safe thanks to the implementation of the best technologies of the moment and if the production cost does not exceed 1.5 times the average production cost of electricity in the country, all power plants considered: nuclear, fossil, hydroelectric, etc.

[16] World electricity production in 2019: 26,413 TWh. Source: Our World in Data, https://ourworldindata.org

[17] Like any other human activity, wind power production competes with other uses useful to the population: agriculture, livestock farming, housing, industrial and commercial zones, transport routes: roads, motorways, airport approach zones, radio transmission zones, etc. and, more specifically for offshore wind power, fishing and navigation zones.

[18] Nominal unit power expressed in MW of wind turbines marketed today.

[19] Air density: 1.292 kg/m3 , dry air at a temperature of 0 °C and under normal atmospheric pressure.

[20] Albert BETZ(25 December 1885 – 16 April 1968) was a German physicist. Working at the Technical University of Berlin, he invested in the exploitation of wind energy and in the operation of wind turbines. In 1920 he established the BETZ formula: at most, 16/27th of the kinetic energy of the wind upstream of the wind turbine operating in an open environment can be transformed into mechanical energy.

[21] Unlike a technological breakthrough, which represents a profound change in the technology or the industrial process used, incremental progress characterises an evolution by stages which brings a quantifiable improvement without calling into question the basic concept.

[22] The term “pit” refers to the movable part at the tip of the blade, which can be oriented parallel to the wind direction by means of a safety system, in order to brake and then stop the rotation of the rotor in case of strong gusts of wind or lack of voltage on the public grid (absence of resistive electric torque). When the wind generator is stopped, the mechanical brake (clamping of the transmission shaft) can be activated and the machine is then in a safety position.

[23] Stall control: In the case of fixed blades, this refers to a passive aerodynamic control principle which is based on the blade profile designed to prevent stalling in low wind conditions and runaway when the wind speed increases.

[24] Pitch control: In the case of blades with a variable pitch or angle of attack, this is an active aerodynamic control principle. It allows the power output of the wind generator to be regulated according to the wind speed, in particular to limit the power when the wind becomes strong or to stop the machine in case of strong winds by placing the blades “feathered” parallel to the wind direction, thus reducing the wind load.

[25] The blade tip spoiler has become a common feature of modern wind turbines. It improves the aerodynamics of the blades and consequently the energy conversion efficiency of the machine. It also reduces the noise due to the airflow.

[26] HORSIN MOLINARO, H. and MULTON, B., Energie électrique : génération éolienne, July 2020, Sciences de l’Ingénieur, École Normale Supérieure Paris – Saclay,

[27] The installation of wind turbines does not prevent the use of the land for certain purposes after the work has been completed. Agricultural activities can be maintained: crops, livestock, etc. On the other hand, residential, commercial and industrial areas, as well as roads, must be kept at a distance, mainly for reasons of noise and safety.

[28] BESLIN, G., 2021, Impacts de la production éolienne. Quel bilan en 2020 ? Quelles perspectives ?, Encyclopédie de l’Environnement, www. encyclopedie-environnement.org

[29] Source: IEA Wind Technology Collaboration Program (TCP), Annual Report 2019, Wind Database, International Energy Agency, www.iea.org

[30] Considering an average wind speed of 7.5 to 8.5 m/s (Weibull distribution, IEC Class II), the rotor diameter of the best technology wind turbines currently on the market is between 115 and 125 m, with a rated power of between 3.5 and 4.5 MW.

[31] In 2020, a jury elected the “best” wind turbine of the year. This was an opportunity for the awarded manufacturer to recall the trajectory of wind turbines for land-based sites marketed since the early 1980s.

[32] The mast is in most cases made of steel. There are some wind turbine models with reinforced concrete masts.

[33] For land-based sites with particularly strong and turbulent wind regimes with the probability of violent gusts, on certain islands and in cyclonic regions, wind turbines of smaller dimensions and nominal power are installed with characteristics that correspond to the local wind resource. These so-called cyclonic wind turbines sometimes have two blades and their mast is foldable.

[34] In many countries, especially in the EU, the wind turbine delivers electricity at LV (690 V) up to a nominal power of about 5 MW; then the voltage is raised to HV (20 kV) to reach the internal wind power grid or the public distribution grid.

[35] “Grey energy” is the amount of equivalent energy expended during the initial phase of site development, manufacturing of the wind turbines and other related equipment (e.g. energy delivery station), foundation construction, etc. and during deconstruction (dismantling work). The calculation of the “grey” energy related to an electricity production facility therefore excludes the consumption of carbon energy – in the case of fossil power plants – which is directly involved in the electricity production process during the operating phase, which is zero in the case of wind power production.

[36] In many countries, especially in the OECD and the EU, the obligations of the developer to ensure the construction of the wind farm and, after the operating period, the dismantling of the equipment are defined in the building permit. This is the case in France.

[37] For offshore: grey energy is more complex to estimate. It depends on the site: depth of the sea, distance from the coast, nature of the subsoil, type of foundation: gravity, monopile, tripod, floating structure, etc.

[38] Source: L’éolien, Commission énergie, France, https://energie.eelv.fr/la-transition-energetique/comment/leolien/ International studies (IPCC) place the CO2 content of the wind kWh around 10 grams.

[39] Source: Bilan Électrique de la France, 2020, Réseau de Transport d’Électricité, www.rte-france.com

[40] This is the average annual productivity of onshore wind power installations. This production range (1,700 to 2,200 MWh per MW of installed capacity per year) covers the majority of recent wind power installations in EU countries. From this, the average annual load factor is deduced, which is therefore between 19.4% and 25.1%. For offshore wind installations, the average annual load factor is higher, between 2,800 and 3,200 h/year, to the benefit of the offshore wind field which is more regular.

[41] LCOE: Levelized Cost Of Energy, i.e. the average production cost discounted over the operating life of the production facility (20 years for the vast majority of sites). This cost takes into account the investment cost (CAPEX), the operating and maintenance expenses (OPEX) and the decommissioning cost, discounted to the discounted turnover over the operating period of the electricity production facility.

[42] Source: https: //energie.eelv.fr/la-transition-energetique/comment/leolien/

[43] This is the grey energy as mentioned above. The actual industrial process of converting the wind resource into electricity is CO2-free.

The Encyclopedia of the Environment by the Association des Encyclopédies de l'Environnement et de l'Énergie (www.a3e.fr), contractually linked to the University of Grenoble Alpes and Grenoble INP, and sponsored by the French Academy of Sciences.

To cite this article: BESLIN Guy (January 5, 2025), From wind energy to electricity generation, Encyclopedia of the Environment, Accessed April 2, 2025 [online ISSN 2555-0950] url : https://www.encyclopedie-environnement.org/en/air-en/from-wind-energy-to-electricity-generation/.

The articles in the Encyclopedia of the Environment are made available under the terms of the Creative Commons BY-NC-SA license, which authorizes reproduction subject to: citing the source, not making commercial use of them, sharing identical initial conditions, reproducing at each reuse or distribution the mention of this Creative Commons BY-NC-SA license.