工程师眼中的土

由于地球土壤的多样性,具有专业知识的工程师应当与其他领域的专家一起开展土木工程项目。这位专家强调了需要考虑的土体特性,并通过适当的测试对其进行表征,以确保土木工程结构的基础在足够稳定的同时兼具一定的安全储备。值得注意的是,他提供了一个能够模拟结构使用寿命期间内土体和结构间相互作用的工具。此外,对周围场地的勘测能够记录建筑物整个生命周期中基础的状况和可能产生的位移。如今,我们通过对土体的改良和加固,可以在任何曾经被认为不适合的区域建造超大型构筑物。在当前建筑方法的指导下,建设工程对城市地区的破坏越来越小,这使得我们可以将工程建设的极限延伸至想象范围之外。

1. 为什么土备受关注

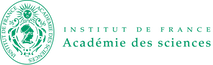

[来源:皮埃奇(A. Puech),2008,海洋岩土工程课程,ENSHMG]

让我们先来谈谈建筑:所有的主要地面结构(大坝、桥梁、高架桥、高层塔楼、筒仓、石油和化学品仓库、发电厂……)都需要地基。对于地下结构而言(隧道、地下巷道、地下工厂、储气罐……),它们必须承受来自地面的作用(通常称为压力)。最后,受海洋因素影响的海上构筑物的稳定性也是基于其所在海床上的支撑作用(重力式结构,图 1)或是构筑物与海床的锚固(浮动结构,导管架,图 2;或单桩,图 1,石油管道)。

然而,土壤是一种“有生命的”的物质,会在各种自然和人为的影响下,随着时间的推移而变化,这些变化有些是可以被我们预知的,而有些则是出乎我们意料的。因此,我们还必须对与结构接触的土体进行加固处理,以及对可能发生的破坏进行补救。

[来源:皮埃奇(A. Puech),2008,海洋岩土工程课程,ENSHMG]

一名专业的工程师(岩土工程师,通常是一个岩土工程师团队)主要负责解决土壤和构筑物之间相互作用(土-结构共同作用)的问题。这也决定了他与负责项目本身的团队有着密切的联系。为了方便起见,在本文的以下部分中我们将使用“工程师”一词来指代岩土工程师。

当提出建造一个理论上可行的大型土木工程结构的想法时,初级设计阶段的部分工作便在于仔细核算构筑物可能承受的环境影响及其对周边环境的改造。因此,工程师们必须要查阅当地有关自然现象(雨、雪、干旱、洪水、风暴、冻融、地震、爆炸等)的年鉴。这些自然现象可能会随着时间的推移导致构筑物变形和影响其稳定性。然而,更加全面的影响研究(如物理、水力、生态、社会经济等)对于评估工程对附近及远距离环境的影响也是至关重要的。此时,个体利益和整体利益间经常存在冲突。例如,阿斯旺大坝的建成彻底改变了埃及的农业条件:对尼罗河上游的农业影响是有利的(灌溉),但对尼罗河下游农业的影响则是灾难性的(土地盐碱化,每年肥沃冲积物的缺乏)。

因此,如果建设方案没有根本性的错误,我们就将进入项目阶段(包括结构的精确设计及其与地面相互作用的分析)。

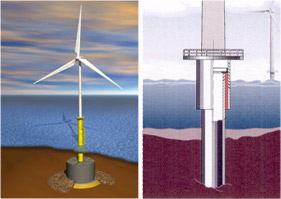

[来源:左,法国大坝和水库委员会,2012,大坝技术];[右,杜歇昆汀(Douchet Quentin)GFDL(http://www.gnu.org/copyleft/fdl.html)或CC BY-SA 3.0(http://creativecommons.org/licenses/by-sa/3.0)]通过维基共享。(图1左:coupe transversale横截面,plate forme aval下游平台,rembial de pied aval下游堤防,drain exutoire引流管排水,recharge aval en éboulis下游充填碎石,parement en enrochements抛石壁板,altuvions冲积层,moraine底碛,drain incline排水坡度,galerie sous fluviale河道下廊道,voile de drainage排水罩,voiles d’injection喷射帆,630m environ约630米,CRISTALLIN: gneiss结晶状:片麻岩,retenue normale: 1695 NGF正常保留1695 NGF,filter fin过滤结束,zone principale en enrochements主要填岩区,protection en enrochements choisis在选定的岩石中进行保护,niveau inimal of exploitation normale:1951最低正常运行水平:1951,batardeau amont: 1575上游码头:1575,decharge amout垃圾填埋体积,zone intermediaire en eboulis中间碎石区,galerie d’injections et de controic注射和控制回廊,contact lias/cristallin接触束/晶状)

我们所提到的术语“土”,是指位于植物层和/或陆地有机层之下的土壤和岩石。它们是天然材料,从矿物学、粒径、可能的胶结作用以及形成的整个历史来看,都各不相同。然而,根据属性的相似性可以将它们划分为砾石、砂、粉砂、粘土、硬度及构造程度差异显著的岩石。水几乎总是存在于这些土体当中,它们使土体饱和(在地下水位以下),或随空气一同赋存于(非饱和土)地下水位之上。在土石坝中(图 3),工程材料是根据所处区域仔细挑选的。

2. 土的重要特性及其表征

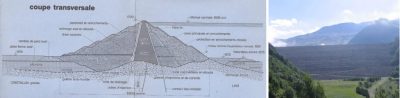

在工程项目中,工程师最重要的工具就是力学。因此,他们格外关注土的力学和水力学特性,即土的刚度(弹性模量)、强度(内聚力(黏聚力)和摩擦力)、膨胀或收缩时的破裂倾向、渗透性和水合/脱水反应。这些特性的各向异性通常也应当给予考虑。土壤孔隙压力的存在要求工程师们同时考虑土的总应力和有效应力,后者是由土骨架实际承受的应力。

[来源:马可波罗(Marc Boulon)](Compression verticale纵向压缩,Pierre poreuse多孔岩体,Membrane élastique étanche防水弹性膜,Pression p de cellule autour de l’échantillon样品所受围压p,Cellule sous pression p压力仓,Echantillon de sol岩土样品,Drainage ou mesure de pression interstitielle排水或孔隙压力测量)

陆地建筑的初步设计需要对现场的土进行鉴定,即岩土勘测。工程师首先要从地质学家那里获取自己的第一手资料,以及以往邻近建筑的文件(如果可以得到的话),最后工程师必须进行钻孔/岩心取样(用于实验室测试:图 4 三轴试验, 直剪试验、固结试验等)或原位测试(透度计、旁压仪、震波折射等)。

实验室测试能够直接提供土体的水力学数据。另一方面,原位测试则只能通过与水力学参数的相关性来解释,因此具有一定的不确定性。水深测量、透度计测试和旁压仪测试可以提供土体的局部信息(垂直方向),而良好的地震波测试则可以提供关于土体质量的信息,能够反映土体的不均匀性。此外,还有许多其他技术也可以用来获取地下土层的特征:电导率测试、重力测量、雷达探测,这些技术也有助于探测地下孔洞和断层、裂缝等不连续现象。

3. 土工分析工具设计

通常,我们会谈论工程中的建筑(桥梁、大坝、电站等),以及能够支撑甚至成为建筑一部分的地面(例如土坝)。在建筑的整个使用周期中,土-结构共同作用是永久性的。

根据现场土的特性(§2),工程师评估地面现有结构的现状和附加荷载。然后,通过设置一个或多个安全系数来确定工程和结构的尺寸,这些安全系数是通过增加荷载或降低土体强度的方式来估算破坏情况而获得的。在同时考虑历史上曾发生过的破坏事件和工程事故,基于适当的记录和考虑从而制定并完善的国家和国际标准(包括欧洲标准、欧洲土壤标准 7)能够对建筑的安全性进行评估。但是,在任何形式的破坏发生之前,土体和建筑的实际变形也会影响建筑的“健康”。

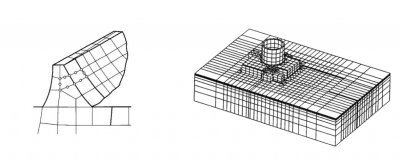

[来源:MESTAT, P., (1997),有限元网格, 建议和推荐, BLPC 212, 39-64]

工程师可以使用各种工具,通过传统或更先进的方法对建筑和周围地区的情况进行建模。值得注意的是,获益于专业人员和研究人员之间的交流,这些方法不断被改进。传统方法主要以安全为导向。他们假设土体是一种刚性材料,也就是说,其在突然破裂之前不会发生变形。较新的数值方法(特别是有限元方法, 图 5)提供完整的土的本构关系,反映土体变形直至破裂,以及破裂本身的状态。这些本构模型提供了对处于使用过程中的建筑和地面(通常是大坝及其附近的山谷)进行安全评估和变形情况预测的途径。如今,传统方法和现代方法在这个行业中共存。

我们刚刚提到的数值建模(有限元)对于工程师来说是一个很好的预测工具。但只有在能提供具有代表性的流体力学参数情况下,其预测结果才能令人满意。然而,由于地基的非均质性,在项目过程中,土壤的初始特征(§4)总是近似的。例如,从事隧道或巷道挖掘工作的矿工会告诉你,只有在实际开挖的时候才能真正知道地下是什么样的。这就给了有限元数值模拟可以发挥作用的空间。我们对工程的各阶段(连续的施工阶段)进行了模拟,并将结果与工程期间的现场监测结果进行比较,并从开始阶段起(在未开挖的场地),对土体的水力学变量(位移、应力、孔隙压力等)进行修正。这为反演分析提供了基础,允许在施工过程中对岩土工程参数进行修正。这使得构筑物在使用和特殊载荷下的表现得到了更真实的明确模拟。这种所谓的实地观测方法也可让我们重新审视最初的项目设计,以防当初过于大胆而使项目不符合安全标准。

4. 建筑和土体的诊断

前面已经提及了伴随建设过程的一些措施,包括用于地面的和用于建筑本身的措施(§3)。但是,建筑及其周围区域在竣工后的使用期限会很长。对于大型工程,以及正在进行的和已确定的风险情况(滑坡、岩崩等),通常会对现场流体力学变量进行程序化测量,从而构成诊断。。这种方法需要快速解读和实时传播才能发挥最大的价值。因此,滑坡发生时,在荷载不变的情况下发生加速移动意味着土体正在快速趋于突然破裂,此时应该向受威胁人口发出预警。最常见的工程诊断对象(及其所在区域)包括大坝(及其形成山谷的斜坡)、水电站、桥梁及高架桥(不均匀沉降问题)、隧道和地下巷道(由于结构穿过的断层运动或周围岩性的改变,确保了其计算结果有限的收敛)。在诊断过程中涉及到的设备有引伸计、倾斜仪、沉降仪、孔隙压力和地下水位传感器、地形测量工具等。

在过去(以世纪为单位),工程师可以使用粗糙的测量仪器进行测量(利用经纬仪测量位移,用水准仪测量倾斜等)。这些粗测的方法现在已经慢慢被淘汰, 这也证明了现在我们的测量技术日渐精细和有效。新技术在岩土工程中占有了重要的地位。如今,地表位移可以通过 GPS 进行快速、自动、准确的测量。延伸测量和倾斜测量则可以使用光纤实现。在隧道或巷道中,所有的引导和收敛测量都是基于激光技术实现的。无人机和图像分析技术也被用于监测大型边坡(大坝、桥梁等)的状态。此外,还有许多其他新技术也有望在未来的诊断工具中得到应用。

5. 土体的改良与加固

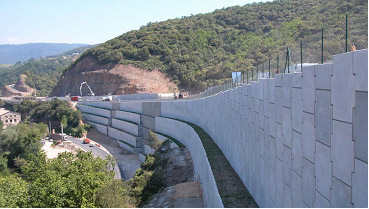

[来源:卢卡斯(E. Lucas), 谢雷(P. Sery),(提古利特)A. Tigoulet, (布朗卡)D. Brancaz, 2008,最近的高加固土结构,JNGG 2008,南特]

我们可以通过预防性加固对建筑以下或邻近地区土体的预期变形及非预期变形进行矫正。预防性加固的方法有很多,我们就以压实为例,这是一种通过滚轮振动或施加动荷载(利用重物击实,地面震动击实)方式对地面进行的加固处理。对于细颗粒含量高的含水土体,加固操作则是在排水、电渗透系统或是不透水表面膜下利用大气压力形成的真空条件下进行。在这个过程中,工程师必须始终保持耐心!用土工布、微桩、土钉进行加固是很常见的。特别是在钻孔过程中使用密封钢筋,无论是被动的还是主动的(密封后张拉),都被广泛用于稳定岩石边坡和敏感的隧道围岩。在公路和高速公路沿线经常会遇到加固路堤(图 6)。

[左,来源:大卫毛尼克斯(David Monniaux)(自己的作品)[GFDL(http://www.gnu.org/copyleft/fdl.html),CC- By -sa -3.0 (http://creativecommons.org/licenses/by-sa/3.0/)或CC- By -sa 2.0 en (http://creativecommons.org/licenses/by-sa/2.0/fr/deed.en)],通过维基共享。[右,马可波罗(Marc Boulon)](65 m 65米,pile 地桩,blocs de basalte玄武岩块,pieux桩,substrat argileux泥质基质)

随着时间的推移,无论是否经过规划,对地面变形进行补救的措施都非常常见。为了矫正桥墩之间的沉降差异,需要定期将桥面吊起进行检查。人们还会在埃菲尔铁塔的地基和塔脚之间放置圆柱。墨西哥市中心是一个对地震非常敏感的粘土地区,大型建筑都建在顶部有圆柱体的桩上,以便在每次大地震后纠正建筑的坡度。此外,瑞恩安提瑞恩(Rion Antirion)的斜拉桥(图 7)也被设计成能够承受地震荷载。

在世界上,缓解差异沉降问题最常用的技术是在过度沉降的基础区域下方注入水泥灌浆。但最近又出现了另一种原创技术。比萨斜塔和墨西哥城大教堂建在一层厚厚的黏土之上,令人担忧是它们的倾斜程度还在不断增加。该问题在一定程度上是通过在最高的地基下进行地下开挖或粘土提取来进行处理的。这样做的目的并不是为了将这些建筑复原如初,而只是为了保持它们的倾斜度(既要确保建筑的安全还不能影响到建筑的旅游收入等)。

6. 发展前沿与趋势

[来源:photopqr / le progress / philippon joel]

在一般情况下,非开挖工程比土方工程更受欢迎,因为非开挖工程通常不会对居民造成影响。从小直径到大直径,我们都可以定向钻井,例如,如果土体条件合适,我们可以在路堤、公路、铁路甚至河流下安装非直线(公制直径) 管道。这时,微型隧道机能为挖掘公制巷道提供一个有趣的视角。最后,十米制尺寸的隧道掘进机(图 8),即使是在非常软的(沙、粘土),饱和的(英吉利海峡隧道),非常浅的(楔石距离地面不到 10 米)或非常深的(瑞士圣哥达隧道,里昂-都灵铁路隧道项目,最大可覆盖 2500 米深的岩石和水!)的地方都可以用于建造隧道。所有这些新工具都是能源密集型的!

桩(钻孔桩或压入桩)是软土地基的首选地基处理方法。通常桩的直径可达几米,在海上工程中则可达 100 米。因为循环软化现象的存在,针对循环载荷的研究一直十分活跃。只要条件允许,桩基础承受荷载的能力可以没有上限,但结构本身性质的变化会限制这种能力的增长。例如,工程师会优先考虑自稳定斜拉桥和高架桥(米洛,里昂-安提里翁)而不是悬索桥。

目前,我们正在陆地上试验具有作为地基和热交换器双重功能的地热桩和构筑物。

许多其他的创新即将到来,并为我们开启一个全新的时代……

参考资料及说明

封面照片:大房子大坝,杜歇昆汀(Douchet Quentin)[GFDL or CC BY-SA 3.0],通过维基共享。

环境百科全书由环境和能源百科全书协会出版 (www.a3e.fr),该协会与格勒诺布尔阿尔卑斯大学和格勒诺布尔INP有合同关系,并由法国科学院赞助。

引用这篇文章: BOULON Marc (2024年3月14日), 工程师眼中的土, 环境百科全书,咨询于 2025年4月6日 [在线ISSN 2555-0950]网址: https://www.encyclopedie-environnement.org/zh/sol-zh/soils-for-engineer/.

环境百科全书中的文章是根据知识共享BY-NC-SA许可条款提供的,该许可授权复制的条件是:引用来源,不作商业使用,共享相同的初始条件,并且在每次重复使用或分发时复制知识共享BY-NC-SA许可声明。